Underfloor Heating Manifolds

What are Underfloor Heating Manifolds?

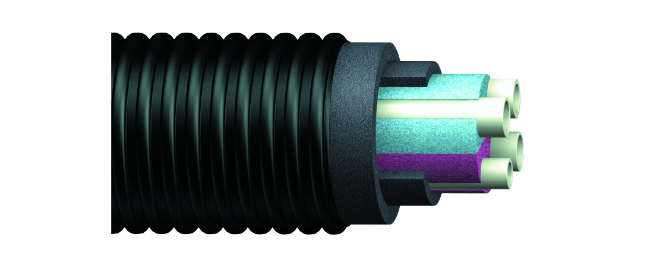

Underfloor heating manifolds are the heart of any underfloor heating system and are used in UFH systems to control the flow of water through the system to provide even, comfortable warmth across the whole floor. Usually consisting of a series of thermostatically controlled 2 port valves, temperature gauges, a mixing valve and a circulation pump; manifolds reduce the installation time by reducing the number of fittings required to connect pipework. Usually, all the pipes within an underfloor heating system will pass through a flow or return manifold to control individual zones within a system.

UFH Manifold Benefits

:• Made for easy installation

• Available in a range of different ports to suit your requirements

• Reliable performance

Manifolds at Underfloor Store

Discover our comprehensive range of high-quality UFH manifolds and pumps at Underfloor Store. Our range includes manifolds from 2 to 12 ports to ensure we have the manifold for your UFH system. Manufactured from quality components, you can be sure that our UFH manifolds are designed to ensure accuracy and reliability. No matter the size of the underfloor heating system, our range of manifolds are suitable for small single rooms to large commercial properties. Here at Underfloor Store we only sell recognised and trusted brands such as Uponor, Warmus and Polypipe, so you can rely on us to provide high-quality manifolds from only the best industry brands. To shop our manifolds visit Underfloor Store today.

Pumps and Blenders at Underfloor Store

For many underfloor heating systems, the water is pumped and blended locally at the manifold; this is achieved by combining a pump and blender unit with the manifold. Here at Underfloor Store, we sell a range of Pumps and Blenders which can be used in conjunction with our UFH manifolds. All designed to be lightweight and compact in order to connect directly to the manifold to circulate and control the underfloor water temperature; our pumps and blenders provide a quick and easy installation.

Wet Underfloor Heating Kits and Products

If you are installing a whole new wet underfloor heating system then no need to purchase all the components for your new system separately as we have done all the hard work for you. Our wet underfloor heating kits come with all the components you’ll need to install your wet underfloor heating system, including the UFH manifold, control pack and pump, ball values, compression adaptors, pipe, pipe clips and edging strip. Our kits are guaranteed to save you money as well as time, as we have taken away all the stress and hassle when it comes to sourcing and ordering the induvial components for your new underfloor heating system. To view our wet underfloor heating kits visit Underfloor Store today.

Underfloor Heating Spares

We understand how frustrating it can be when you require a spare but can’t source it. That’s why if you ever require a spare for your UFH manifold then we can help. Here at Underfloor Store, we stock a huge range of spares in case you ever require a replacement part. Our spares include:

• Uponor spares

• Polypipe spares

• WarmUs spares

• Wirsbo WGF manifold spares

• Uponor MF manifold spares

• Uponor FM and FR manifold spares

• Uponor TM manifold spares

Contact Underfloor Store

If you are looking to purchase UFH manifolds or a complete wet underfloor heating kit then visit Underfloor Store today where you can browse our huge range of products and kits. We also like to go the extra mile here at Underfloor Store; that is why we provide support and advice to all our customers. So if you need some help on how to install your new kit or manifold simply get in touch today on 0330 123 2231 and speak to one of our friendly and knowledgeable team who will be more than happy to help you with any enquiry you may have.